Svenska I English

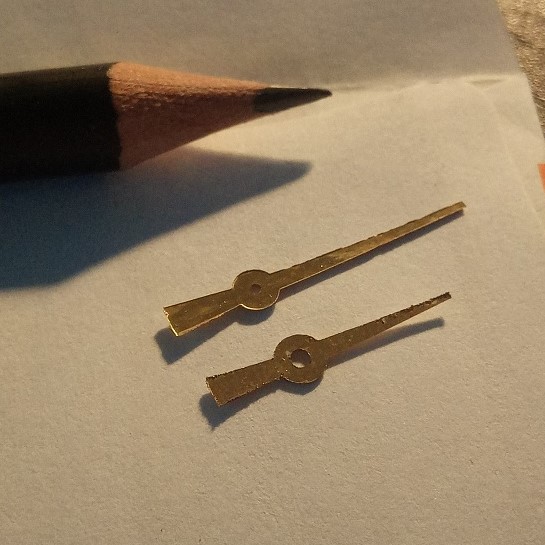

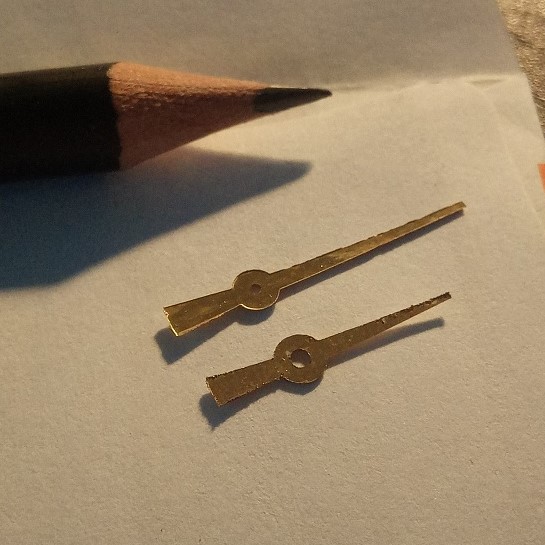

Have you ever wondered how the watches in Levenaig’s collection are made? This page offers you some glimpses behind the scenes of Levenaig. Below is a selection of snapshots from my little workshop. More images may be added later.

Handmade in Sweden

Svenska I English

Have you ever wondered how the watches in Levenaig’s collection are made? This page offers you some glimpses behind the scenes of Levenaig. Below is a selection of snapshots from my little workshop. More images may be added later.